Hydraulic pole saws are essential tools for pruning and cutting trees, allowing you to reach high branches without using a ladder. Like all power equipment, keeping your hydraulic pole saw in top condition is critical for both its performance and longevity. In this article, we’ll guide you through the essential maintenance steps to ensure your hydraulic pole saw remains reliable and efficient for years to come.

Table of Contents

Introduction

A hydraulic pole saw is a powerful tool designed for trimming and cutting branches in hard-to-reach areas. Powered by hydraulic pressure, it offers unmatched cutting efficiency, durability, and precision, making it an essential choice for professional arborists and landscapers. Whether tackling tough tree care tasks or routine maintenance, a hydraulic pole saw ensures reliability and ease of use in demanding conditions.

1. Regularly Inspect the Hydraulic System

The hydraulic system is the heart of a hydraulic pole saw. Over time, it can wear down or become clogged. To maintain optimal performance, make it a habit to inspect the hydraulic components regularly. Check for any signs of leaks, cracks, or damaged hoses. If you notice any issues, it’s important to address them immediately to avoid potential malfunctions.

- Check fluid levels: Ensure the hydraulic fluid is at the recommended level. Low fluid can lead to poor performance and even damage the system.

- Replace dirty or contaminated fluid: If the hydraulic fluid appears dirty or has particles floating in it, replace it as soon as possible. Contaminants can cause wear and tear on the internal components.

2. Sharpen the Blade for Clean Cuts

A sharp blade is essential for efficient cutting. Over time, the blade on your hydraulic pole saw can become dull, leading to inefficient cuts and increased wear on the motor. Sharpen the blade at least once a season, or more frequently if you use the saw often.

- Use a sharpening tool: You can use a specialized sharpening tool or file to maintain the blade’s sharpness.

- Check for wear and tear: If the blade is excessively worn or chipped, consider replacing it.

3. Clean the Pole Saw After Every Use

Keeping your hydraulic pole saw clean is crucial for preventing dirt and debris from affecting its performance. After each use, wipe down the pole saw and remove any sticky sap or dirt from the blade and hydraulic components.

- Use a damp cloth: A soft, damp cloth can effectively remove most debris.

- Clean the chain: Use a chain cleaning solution to remove any built-up sap and dirt from the chain. This will keep it running smoothly and prevent rust.

4. Lubricate Moving Parts

Lubrication is key to keeping the moving parts of your hydraulic pole saw in good condition. Regularly oil the chain, sprockets, and other moving components to reduce friction and prevent premature wear.

- Use the right lubricant: Always use a lubricant recommended by the manufacturer to ensure compatibility with your hydraulic system.

- Apply regularly: Make lubrication part of your routine maintenance, especially after heavy use.

5. Check the Safety Features

Safety should always be your top priority when using power tools like hydraulic pole saws. Ensure that all safety features, such as the chain brake and safety switch, are functioning properly. A malfunctioning safety feature can lead to accidents, so it’s important to address any issues immediately.

- Test the chain brake: The chain brake should engage when you stop cutting. If it’s not functioning correctly, have it repaired.

- Inspect the safety switch: Ensure the safety switch is responsive and in good condition to prevent accidental starts.

6. Store the Pole Saw Correctly

Proper storage is crucial for maintaining the integrity of your hydraulic pole saw. When you’re not using it, store it in a cool, dry place to avoid rust and corrosion. If you’re storing it for a long period, drain the hydraulic fluid and clean the saw thoroughly before storage.

- Use a protective cover: A cover can protect your pole saw from dust and environmental factors when not in use.

- Store in a dry location: Avoid storing your saw in a damp or humid environment to prevent rust on the blades and metal parts.

7. Regularly Test Performance

Once you’ve performed all maintenance tasks, it’s important to test your pole saw’s performance. Start the saw and check for smooth operation, proper cutting speed, and responsiveness. If the saw is not performing as expected, it may indicate an underlying issue that needs further attention.

- Test hydraulic performance: The hydraulic system should provide smooth and consistent power to the saw. Any hesitation or irregular movement may indicate a need for further inspection or fluid change.

- Check the cutting power: The saw should cut efficiently without excessive strain. If you notice reduced cutting performance, it might be time to replace the blade or sharpen it.

Pros

Cons

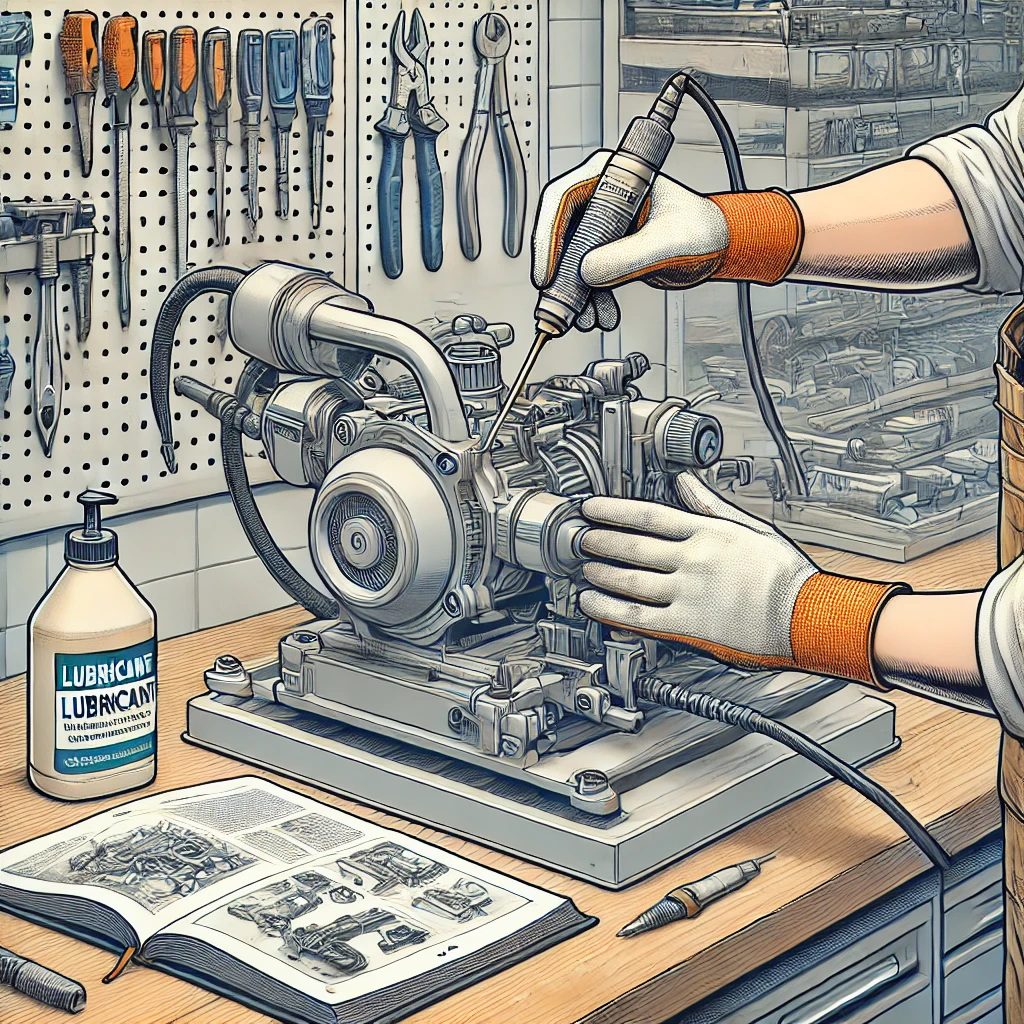

How to Lubricate Hydraulic Saws: A Step-by-Step Guide

Lubricating your hydraulic saw is crucial to ensuring its longevity and optimal performance. Proper lubrication reduces friction, prevents wear and tear, and keeps the system running smoothly. Whether you’re a professional in tree care or a DIY enthusiast, learning how to lubricate your hydraulic saw correctly can save you time and money on repairs. In this step-by-step guide, we’ll walk you through the essential lubrication process for hydraulic saws, ensuring that your tool stays in top condition.

You may also like

Why Lubrication is Important for Hydraulic Saws

Hydraulic saws rely on hydraulic fluid to power the cutting mechanism. However, like all machines with moving parts, they need proper lubrication to minimize friction between components and to prevent rust or corrosion. Neglecting lubrication can lead to decreased performance, overheating, and even damage to the hydraulic system, making regular maintenance a critical part of ownership.

Step 1: Gather the Necessary Tools and Materials

Before you begin lubricating your hydraulic saw, ensure you have all the necessary materials at hand. This will make the process quicker and more efficient.

- Recommended lubricant: Always use the lubricant recommended by the manufacturer. Hydraulic saws require specific types of oils to maintain their system.

- Rags or cloths: Use soft rags to wipe away any old or excess lubricant.

- Cleaning brush: For cleaning the chain and other components before lubricating.

- Grease gun or oil can: Depending on your saw’s lubrication system, you may need a grease gun to apply grease or an oil can for hydraulic fluid.

Step 2: Power Down and Disconnect the Saw

Safety should always come first. Before starting any maintenance, ensure the hydraulic saw is powered off and disconnected from its power source. If you’re using a gas-powered saw, turn off the engine. For electric saws, disconnect the power cord or remove the battery.

- Disconnect the hydraulic system: If your saw is connected to a hydraulic system, turn it off to prevent any accidental pressure buildup while you’re working on it.

Step 3: Clean the Components Before Lubricating

Before applying any lubrication, it’s essential to clean your saw. Over time, dirt and debris can accumulate on the moving parts, preventing the lubricant from effectively doing its job. Here’s how to clean your saw before applying fresh grease:

- Clean the chain and guide bar: Use a cleaning brush to remove any dirt or sap buildup on the chain and guide bar.

- Wipe down the saw body: Use a rag to wipe down the body of the saw, removing any dust or old lubricant.

- Inspect for damage: While cleaning, check for signs of wear, cracks, or other damage. If anything appears worn out, replace it before proceeding.

Step 4: Apply Lubricant to the Chain and Guide Bar

Now that your hydraulic saw is clean, it’s time to apply the lubricant to the moving parts. Follow these steps for proper lubrication:

- Lubricate the chain: Using a grease gun or oil can, apply a generous amount of lubricant to the chain. Ensure that the oil is spread evenly across the entire length of the chain.

- Lubricate the guide bar: The guide bar is another essential component that requires lubrication. Apply lubricant to the grooves of the bar, making sure to cover all areas that experience friction during use.

- Check for excess oil: After applying the lubricant, check for any excess oil and wipe away the surplus with a rag to prevent it from attracting dirt and debris.

Step 5: Lubricate the Hydraulic System (If Applicable)

If your hydraulic saw uses a hydraulic system for power, it’s crucial to keep it properly lubricated. Follow these steps to ensure the hydraulic components are well-lubricated:

- Check hydraulic fluid levels: Before applying any new lubricant, inspect the hydraulic fluid levels. Low fluid levels can lead to overheating and poor saw performance. Refill the hydraulic system with the recommended hydraulic fluid.

- Lubricate the hydraulic pump: Some hydraulic saws have lubrication points on the hydraulic pump. Use a grease gun to apply grease to these points, ensuring that the pump moves smoothly without friction.

Step 6: Test the Saw

Once you’ve lubricated all the necessary components, it’s time to test your hydraulic saw:

- Start the saw: Power up the saw and listen for smooth operation. If the saw operates without unusual noises or jerky movements, your lubrication has been successful.

- Check for leaks: Inspect the saw to make sure there are no hydraulic fluid leaks, especially around the hoses or connections.

- Perform a cutting test: If everything seems in working order, perform a quick cutting test to ensure the saw is running efficiently and that the lubrication is effective.

Step 7: Regular Maintenance

Regular lubrication is key to keeping your hydraulic saw in optimal working condition. Lubricate your saw after every few uses or according to the manufacturer’s recommendations. Additionally, check the oil levels, clean the saw, and inspect the hydraulic components regularly to ensure that no buildup or wear compromises its performance.

FAQs About Hydraulic Pole Saw Maintenance

- How often should I maintain my hydraulic pole saw?

Maintenance should be performed after every use, with thorough checks at least once a month. - What is the most important maintenance task?

Keeping the hydraulic system clean and checking for leaks is crucial to ensure smooth operation. - What tools are needed for maintenance?

Essential tools include wrenches, cleaning brushes, hydraulic oil, and lubricants. - Can I do the maintenance myself, or should I hire a professional?

Basic maintenance can be done at home, but consult a professional for complex issues like hydraulic system repairs. - What happens if I skip maintenance?

Neglecting maintenance can lead to reduced efficiency, safety hazards, and costly repairs.

Conclusion

Maintaining your hydraulic pole saw is essential for its longevity and your safety. By performing regular inspections, sharpening the blade, cleaning the saw, lubricating moving parts, and checking safety features, you’ll ensure that your pole saw remains in top working condition. Regular maintenance not only extends the life of your saw but also ensures that you can continue to tackle tough pruning jobs with confidence.

Remember, always follow the manufacturer’s maintenance guidelines and take immediate action if you notice any issues. A well-maintained hydraulic pole saw is a reliable tool that will help you efficiently manage your tree care tasks for years to come.

Leave a Reply